Advantages

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Follow Us

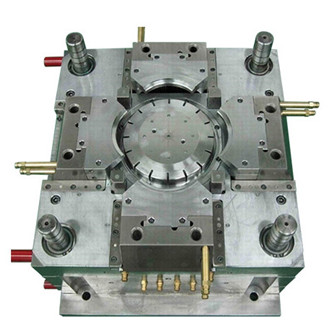

Plastic Injection Mould Design, German Steel, OEM Available

Name: Plastic Injection Mould Design. Mold Material: German Steel. Shape Mode: Plastic Injection Mould. Mould Base: HASCO, DME, RABUDIN, DIN, JIS, LKM. Mould Core: 718, S136, P20, NAK, LKM, EK4, X13T6W,...

German Steel Injection Mould, 718, S136, P20, NAK, LKM, EK4, X13T6W

Name: Injection Mould. Mold Material: German Steel. Shape Mode: Plastic Injection Mould. Mould Core: 718, S136, P20, NAK, LKM, EK4, X13T6W, etc. Mould Making Time: 20-25 Days. Mold Life: 500000-1000000...

German Steel Plastic Mould, DME, HASCO, NEAREST ANSI STANDARD

Name: Plastic Mould. Mold Material: German Steel. Shape Mode: Plastic Injection Mould. Standard Parts: DME, HASCO, NEAREST ANSI STANDARD, NEAREST DIN STANDARD, LKM, etc. Mould Making Time: 20-25 Days....

ABS Plastic Injection Phone Cover Molding, Brush Treatment

Name: Plastic Injection Phone Cover. Material: ABS Plastic, Flame-retardant ABS, HIPS, etc. Manufacturing Method: Plastic Injection. Surface Treatment: Brush, Chrome Plating, Gold Plating,...

PP Plastic Injection Mould Part, PS, HDPE, PMMA, PC, Chrome Plating

Name: Plastic Injection Mould Part. Material: PP, PS, HDPE, PMMA, PC, PVC, etc. Manufacturing Method: Plastic Injection. Surface Treatment: Chrome Plating, Gold Plating, Silver Plating, etc. Color: All...

Plastic Prototyping, PP, PC, PU, PVC, POM, PMMA, Nylon, Painting

Name: Plastic Prototype. Material: Plastic, ABS, PP, PC, PU, PVC, POM, PMMA, Nylon, etc. Surface Finish: Painting, Silk Screening, Electroplating, Anodizing, Sand Blasting, etc. MOQ: 1 pc. Delivery Time:...

About Us

Topper Plastic Mold Co., Ltd. is in business of plastic mold making since 1997, and Topper has its own plastic mold foundry and inection molding plant. Our services include mold design, plastic mold making, plastic injection molding, rapid prototyping, CNC machining, Rubber molding, etc. read moreNews & Events

The Shrinkage Rate of Polypropylene Modified Plastics

Controlling shrinkage rates of polypropylene modified plastics is an important aspect...

read moreArticles

Painting Injection Molding Parts

Injection molding is a widely used manufacturing process that involves injecting molten material into...

read more