The Five Major Business Characteristics of the Plastic Mold Industry

If you want to make money from the plastic mold industry, you will need to pay attention to the five major business characteristics.

With the development of the economy, there is an increasingly fierce competition for the plastic mold industry. A plastic mold expert pointed out that there are five business characteristics of the current mold industry. The single-piece production mode & product differentiation are obvious; average sales of mold manufacturing enterprises are low; there is still a large gap between China's industrial technological level and the developed countries'; plastic mold enterprises are concentrated in an area; upscale mold products are in great demand in China.

The single-piece production mode and product differentiation are obvious

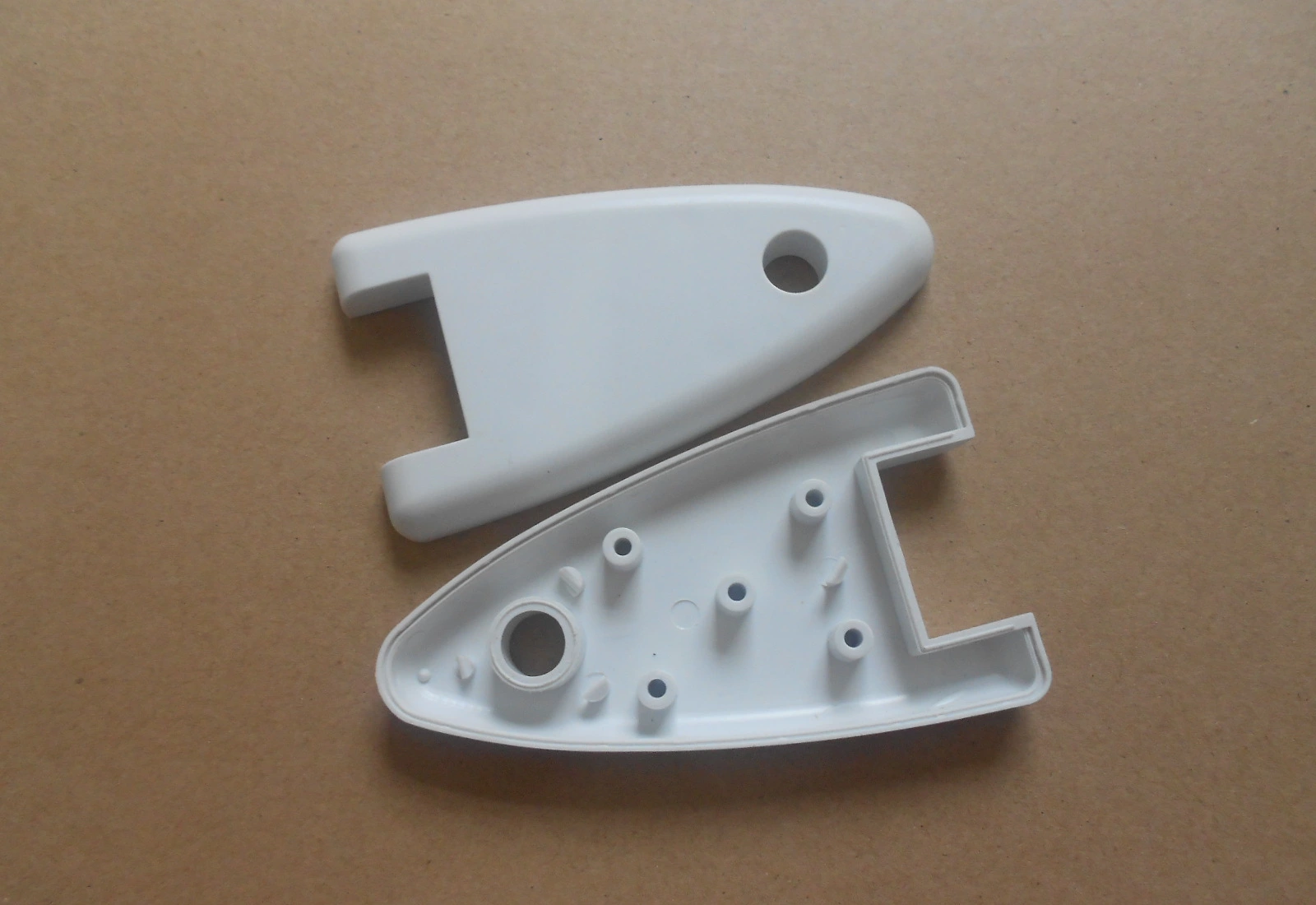

Plastic molds belong to special technological facilities, and each facility is designed for a specific plastic part. Every time when the manufacturers of plastic molds receive an order, they need to design and manufacture a mold according to technical information provided by the customers; that is to say, most of the plastic molds are unique, have obvious product differentiation & high technical requirements and belong to single-piece production.

Average sales of mold manufacturing enterprises are low

Plastic mold industry does not belong to the standardization industry, and the essence of the mold is rationality of the design ideas and the molds' structure. Plastic mold is an industry of high innovation, high-tech, high precision and high added-value. Plastic molds are customized products with strong individuality, and different plastic molds have significant differences.

Therefore, plastic molds have the single-piece production mode. Moreover, plastic molds have relatively long service lives. A set of plastic molds can produce more than 100,000 pieces of plastic products. Therefore, the downstream manufacturing enterprises' demand for the mold products is less, resulting in relatively low sales volumes for the mold enterprises. In 2011, there were about 20,000 plastic mold manufacturers in China based on data provided by China Mold Industry Association. In accordance with the plastic mold industry's total sales volumes which were about 56,000,000,000 Yuan in 2011, average annual sales volumes of plastic mold enterprises were not higher than 3,000,000. The average productivity has small scale, and the industry has the low concentration ratio.

There is still a large gap between China's industrial technological level and the developed countries’

In recent years, the previously extensive pattern of workshop-style which focused on bench workers have been transformed into the intensive pattern of modern style that concentrates on technology and design. Therefore, technological levels of mold industry improve significantly.

Plastic mold enterprises are concentrated in an area

The development of mold industry requires a certain associated upstream and downstream industries. It especially has a very close relationship with downstream manufacturing industry. The mold products belong to intermediate goods, and their customers are mainly terminal products' manufacturers of downstream manufacturing. Therefore, China's plastic mold enterprises are mainly distributed in the Yangtze River Delta, the Pearl River Delta Region and other developed manufacturing areas, among which plastic mold industry in Guangdong, Shanghai, Jiangsu, Zhejiang, Shandong and other provinces & cities are relatively developed, accounting for the vast majority of production value in China's plastic mold industry.

Upscale mold products are in great demand in China

Because there is a certain gap between China's plastic mold technological level and the world's advanced level in the aspects of the plastic molds' quantity, quality and technical capacities, the plastic mold products are mainly concentrated in mid-low-end market, making the domestic demand for imported plastic mold products continue to grow in recent years. Although China's overall plastic mold industry maintains the pattern of trade surplus, we still need to import large, sophisticated, complex and long service life upscale mold products for the domestic demand every year, causing a certain adverse effect on the long-term development of the host industry such as China's automobile and household appliances industries.

With the development of the economy, there is an increasingly fierce competition for the plastic mold industry. A plastic mold expert pointed out that there are five business characteristics of the current mold industry. The single-piece production mode & product differentiation are obvious; average sales of mold manufacturing enterprises are low; there is still a large gap between China's industrial technological level and the developed countries'; plastic mold enterprises are concentrated in an area; upscale mold products are in great demand in China.

The single-piece production mode and product differentiation are obvious

Plastic molds belong to special technological facilities, and each facility is designed for a specific plastic part. Every time when the manufacturers of plastic molds receive an order, they need to design and manufacture a mold according to technical information provided by the customers; that is to say, most of the plastic molds are unique, have obvious product differentiation & high technical requirements and belong to single-piece production.

Average sales of mold manufacturing enterprises are low

Plastic mold industry does not belong to the standardization industry, and the essence of the mold is rationality of the design ideas and the molds' structure. Plastic mold is an industry of high innovation, high-tech, high precision and high added-value. Plastic molds are customized products with strong individuality, and different plastic molds have significant differences.

Therefore, plastic molds have the single-piece production mode. Moreover, plastic molds have relatively long service lives. A set of plastic molds can produce more than 100,000 pieces of plastic products. Therefore, the downstream manufacturing enterprises' demand for the mold products is less, resulting in relatively low sales volumes for the mold enterprises. In 2011, there were about 20,000 plastic mold manufacturers in China based on data provided by China Mold Industry Association. In accordance with the plastic mold industry's total sales volumes which were about 56,000,000,000 Yuan in 2011, average annual sales volumes of plastic mold enterprises were not higher than 3,000,000. The average productivity has small scale, and the industry has the low concentration ratio.

There is still a large gap between China's industrial technological level and the developed countries’

In recent years, the previously extensive pattern of workshop-style which focused on bench workers have been transformed into the intensive pattern of modern style that concentrates on technology and design. Therefore, technological levels of mold industry improve significantly.

Plastic mold enterprises are concentrated in an area

The development of mold industry requires a certain associated upstream and downstream industries. It especially has a very close relationship with downstream manufacturing industry. The mold products belong to intermediate goods, and their customers are mainly terminal products' manufacturers of downstream manufacturing. Therefore, China's plastic mold enterprises are mainly distributed in the Yangtze River Delta, the Pearl River Delta Region and other developed manufacturing areas, among which plastic mold industry in Guangdong, Shanghai, Jiangsu, Zhejiang, Shandong and other provinces & cities are relatively developed, accounting for the vast majority of production value in China's plastic mold industry.

Upscale mold products are in great demand in China

Because there is a certain gap between China's plastic mold technological level and the world's advanced level in the aspects of the plastic molds' quantity, quality and technical capacities, the plastic mold products are mainly concentrated in mid-low-end market, making the domestic demand for imported plastic mold products continue to grow in recent years. Although China's overall plastic mold industry maintains the pattern of trade surplus, we still need to import large, sophisticated, complex and long service life upscale mold products for the domestic demand every year, causing a certain adverse effect on the long-term development of the host industry such as China's automobile and household appliances industries.

Related News

- The Shrinkage Rate of Polypropylene Modified Plastics

- How to Eliminate the Defects of Injection Molded Products?

- Plastic Molded Products

- Cracking of Injection Molded Products

- Several Factors Affecting Plastic Injection Molding Processes (Part two)

- Several Factors Affecting Plastic Injection Molding Processes (Part one)

- Different Plastic Molding

- Plastic molding

- The Classification of the Plastic Gear (Part two)

- The Classification of the Plastic Gear (Part one)

News

Advantages

Low Cost

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Topper is ISO 9001:2008 certified, and Topper processing quality systems ensure that your parts are the highest quality possible for your applications.

Quick Turnaround

Topper offers three different shipping methods, including next day air, to accommodate your timing and budget requirements.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.