News

Advantages

Topper leverages an offshore plastic mold making plant with a lower cost structure in order to offer lower pricing than Topper's competitors.

High Quality

Quick Turnaround

Online Quotes

Topper interactive online quotation system provides instant quotes for plastic mold making, injection molding, CNC machining and die casting.

Follow Us

News

Low Carbon of Stamping Equipment

- Posted: 07/19/2022 11:07:47

- Hits: 11

In the stamping process, the forming equipment produces plastic deformation of the metal sheet through the action of its actuator. The energy consumption of the stamping process is represented by the power consumption of the stamping and forming equipment, and the carbon emission of the stamping process...

Optimization of the Stamping

- Posted: 06/29/2022 01:06:26

- Hits: 8

In the stamping process, the forming of the product will be affected due to the unreasonable design and selection of process parameters, forming defects such as wrinkles, cracks, and burrs. Optimizing the stamping process can reduce the generation of forming defects and improve the quality. At present,...

The Analysis of Energy Consumption of Stamping

- Posted: 06/17/2022 07:06:41

- Hits: 13

Sheet metal stamping parts are widely used in automotive, aerospace, electrical and electronic industries due to their advantages of light weights, high strength, low raw material consumption and high production efficiency. In recent years, the output of automobile stamping parts in China has grown...

Color Changes in Plastic Products Caused by High-temperature Molding

- Posted: 05/13/2022 08:05:40

- Hits: 31

When using color masterbatch to color plastic products, color changes may occur, thus affecting the quality of the product. Analyzing the mechanism of discoloration caused by the following factors provides a reference for plastic part manufacturers to correctly select raw materials and produce...

How to Prevent the Flow Mark for the Injection Molded Part?

- Posted: 03/31/2022 09:03:59

- Hits: 13

The reasons for the flow mark and the measures are as follows: (1) Ring-shaped flow marks occur on the surface of the plastic part due to poor melt flow, which centers on the pouring gate. When the low-temperature and high-viscosity melt with poor flow properties is injected into the cavity...

3D Printing Shortens the Molding Cycle of Gear Products

- Posted: 03/29/2022 09:03:01

- Hits: 9

The cooling of plastic products during injection molding is mainly completed by the mold cooling water channel, but the traditional cooling water channel is manufactured by machining processes such as milling machines. The water channel can only be a cylindrical straight hole, which cannot completely...

The Injection Molding Process of PC

- Posted: 02/27/2022 09:02:28

- Hits: 10

As we all know, PC is commonly known as polycarbonate, which has excellent mechanical properties, so it is commonly known as bulletproof rubber. PC has the characteristics of high mechanical strength, wide operating temperature ranges, good electrical insulation performance, good dimensional stability,...

Influence of Mold Cooling Systems & Ejection Systems on Warpage of Plastic Parts

- Posted: 02/14/2022 04:02:49

- Hits: 12

In the injection molding process, the uneven cooling rate of the plastic part will also cause the uneven shrinkage of the plastic part, which will lead to the generation of bending moment and cause the plastic part to warp. If the temperature difference between the fixed and movable molds is too...

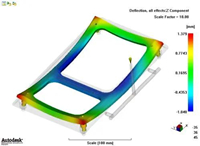

The Influence of the Gating System's Design on Warpage of Plastic Parts

- Posted: 01/22/2022 07:01:20

- Hits: 10

As one of the main indicators to measure the quality of plastic parts, the degree of warpage has attracted more and more attention from designers and end users of plastic parts. Reducing the warpage of products has become one of the key issues that need to be paid attention to in the optimization of...